inclusion rating

Due to the non-metallic inclusion's destruction of the metal matrix's continuity and consistency, it is simple to concentrate stresses, resulting in a reduction in the material's mechanical characteristics and early failure. The inclusion's size, shape, distribution, and aggregation state all have a significant impact on how effective it is. In order to assess the steel's quality, it is important to consider the quantity and distribution of inclusions. Understanding how to evaluate and recognize non-metallic inclusions accurately has become crucial for metallographic testers. OMSPL Lab, an approved third-party testing company, can carry out inclusion rating analysis and testing on steel in accordance with ISO, ASTM, and other standards. Contacting our experts for advice is welcome.

OMSPL's capabilities for inclusion grading include:

- Oxides: FeO, Fe2O3, MnO, SiO2, Al2O3, MgO, Cu2O, etc.

- Sulfides: FeS, MnS, CaS, etc.

- Silicates: 2FeOSiO2, 2MnO.SiO2, CaO.SiO2, etc.

- Nitrides: TiN, ZrN, VN, etc.

The identification methods of inclusions we provide include:

- Combination of Metallographic Method and Micro-area component analysis

-The micro-area composition analysis was carried out with the Electron Probe Micro-analyzer (EPMA) or the Scanning Electron Microscope (SEM) after the unidentified inclusions were chosen in the metallographic observation. Energy Dispersive X-ray Spectroscopy (EDS) was used for the composition analysis. If the surface scanning of individual elements is employed, more logical findings can be produced. It is typically able to identify the constituent elements and approximate components of inclusions whose size is larger than 1 m.

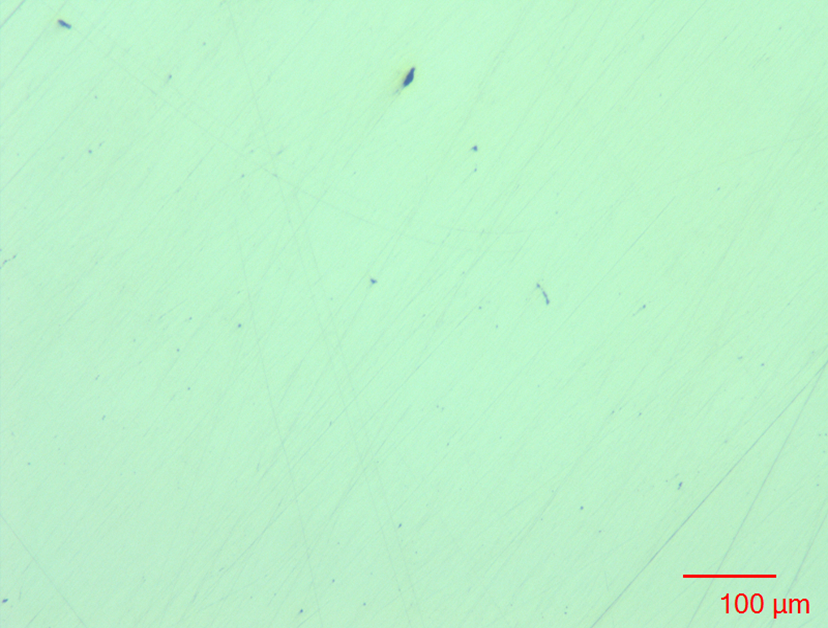

- Optical Metallographic Method

In order to identify the type of inclusion, its colour, shape, size, and distribution are all observed under an optical microscope. The inclusion’s natural colour and transparency are seen in the dark field, and its various optical properties are seen under opposite polarised light. According to the distribution and number of inclusions, the appropriate grade is chosen, and its impact on the qualities of steel is assessed.

Standards we test to

| ASTM E45 – 18a | Standard Test Methods for Determining the Inclusion Content of Steel |

| ASTM E1245 | Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis |

| ISO 3763 | Wrought Steels – Macroscopic Methods for Assessing the Content of Nonmetallic Inclusions |

| ISO 4967 | Steel – Determination of Content of Nonmetallic Inclusions – Micrographic Methods Using Standard Diagrams |