Services

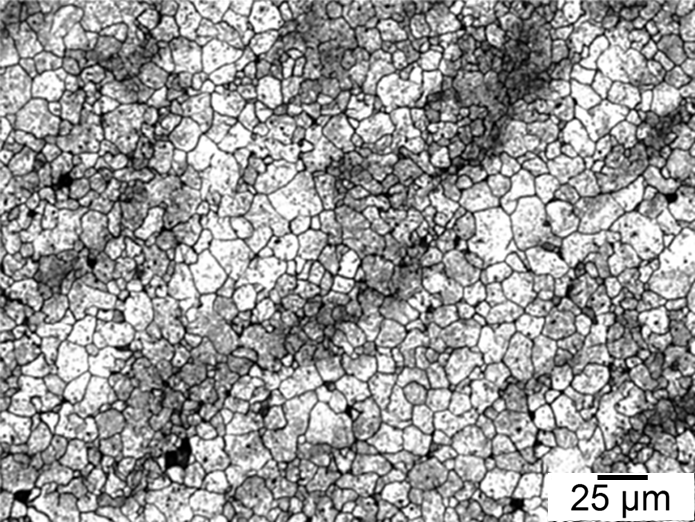

The size and distribution of grains or particles in a substance, usually metals or ceramics, can be found out through a technique called grain size testing. It offers useful details about the microstructure and characteristics of the substance.

There are several common methods for analysing grain size:

- Optical Microscopy: This method involves examining a prepared sample under a microscope and measuring the size of individual grains using a calibrated eyepiece reticle or image analysis software. It provides a quick and relatively low-cost way to determine grain sizes in the range of a few micrometers to several hundred micrometers.

- Electron Backscatter Diffraction (EBSD): Using a technique called electron backscatter diffraction (EBSD), which is based on scanning electron microscopy (SEM), it is possible to simultaneously determine the crystallographic details and grain size. It examines the crystal structure and inclination of individual grains using the diffraction patterns created by electrons interacting with the sample. In the submicron and nanoscale range, EBSD can offer grain size information.

- X-Ray Diffraction (XRD): A technique called X-ray diffractometry (XRD) uses the interaction of X-rays with a material’s crystal lattice to identify its atomic and molecular structure. Although phase identification and crystallography are the two main applications of XRD, it can also give information on the average grain size based on the broadening of diffraction peaks. However, compared to other techniques, it is less frequently utilised for accurate grain size analysis.

- Image Analysis: The size of the grains in images taken using different microscopy techniques can be measured using digital image analysis tools. In this method, the image is divided into individual grains, then the size distribution of those grains is analysed. When there are many grains to examine or when there are intricate grain forms, image analysis is especially helpful.